“1-DAY” CONCRETE COATING SYSTEMS: BEWARE OF WARRANTY EXCLUSIONS

“1-day polyurea” concrete coating systems are extremely popular these days. The idea of having a garage floor coating installed in a single day can be very appealing to the unwary customer. The contractor arrives in the morning and completes installation before the sun sets. But in August of 2020, GarageFloorCoating.com cast a light on the perils of these systems in an article titled Polyurea-Polyaspartic One-Day Systems: Do They Work. The conclusion of the article was simple: “Let the buyer beware”.

How are 1-Day Systems Applied?

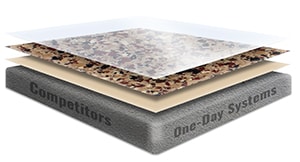

1-day systems use products with fast cure times so that multiple coatings can be applied in quick succession. This is how a “1-day” contractor can install a garage floor coating in a single day. Slower curing products would make for a very long day indeed (or more likely, a 2-day application).

1-day coating systems typically use a fast-curing polyurea as the primer coat and a fast-curing polyaspartic as the clear top coat. (Side note: we like to use the hyphenated words “polyurea-polyaspartic” to describe these products as a polyaspartic is in fact an “aliphatic polyurea”. A polyurea in its pure form reacts so quickly as to be almost unusable (without specialized equipment). Polyaspartic technology utilizes a partially blocked amine to react more slowly with the isocyanates. So a polyaspartic is just a modified polyurea that cures slower. But “slow” is a relative term…as a polyaspartic is still “fast-curing” relative to an epoxy, for example.

In a “1-day” system, sandwiched between the primer coat and clear polyaspartic top coat are the polyvinyl acetate (thermoplastic) “chips”. The applicator broadcasts the chips into the primer while it’s still “wet”. The chips give the final coating its color, texture, and added thickness.

The Limitations of a Polyurea-Polyaspartic

Polyurea-polyaspartic coatings are excellent products. A polyaspartic top coat, for example, can provide extreme UV, chemical and impact resistance and (if it’s a quality polyaspartic that provides dense cross-linking) can prevent staining from hot tire transfer…a common problem in garages.

However, using a polyurea-polyaspartic direct-to-concrete (i.e., as the primer coat) is risky. Concrete is porous and water permeates from the soil beneath, up through the concrete in a process called moisture-vapor transmission (MVT). The resulting hydrostatic pressure can build over time causing blistering, bubbling or peeling of an improperly applied floor. And the thin polyurea-polyaspartic primer coat that “1-day” contractors apply isn’t sufficient to protect the floor against high hydrostatic pressures.

So What Does a “1-Day” Contractor Do?

Simple. “1-Day” contractors provide cover by adding a warranty exclusion (in small print) in their contracts against “moisture-related issues”. So when your “1-day” coating delaminates due to high hydrostatic pressures, the warranty exclusion is invoked. Still, “1-day” systems remain popular with contractors because they use little product and require only 1 day of labor (they’re profitable…just not so much for the customer).

A Proper Way to Apply Concrete Coatings

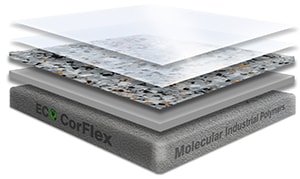

Experienced contractors won’t use a polyurea-polyaspartic direct-to-concrete. Instead, they apply a thick layer of a moisture-mitigating epoxy as the primer coat; the polyurea-polyaspartic is only used as the clear top coat (by the way, we apply 2 coats of clear polyaspartic…not one…to produce an even thicker and more resilient coating). But because the moisture-mitigating epoxy primer has a slower cure rate, at least, slower than a quick-cure polyurea-polyaspartic, the installation time typically spans up to 2 days…not 1.

The Wrap Up

So now you know. Ultra-thin, “1-day” coating systems use a polyurea-polyaspartic direct-to-concrete, so they can’t fully warrant “moisture-related issues”. They also use a fraction of the coating material in the final application. The end result is a garage floor coating that has a higher propensity to delaminate, certainly in the presence of high moisture.

On the contrary, Garden State Garage Floor Coating only applies industrial-grade concrete flooring. We apply our proprietary, moisture-mitigating, 100%-solids epoxy as the primer. We then broadcast your selected mica-infused chip blend (no other contractor offers this) in a full chip spread and top it all with two coats of our 100%-solids polyaspartic clear coat. The result is a 35-mil thick garage floor coating, guaranteed against all moisture-related conditions and tire staining. We have an entire line of industrial-grade polyurea-polyaspartic coatings…and we use them in every garage…as clear tops coats only. Never as direct-to-concrete primers!

Want stunning, industrial-grade, full-chip garage floor coatings with a real lifetime warranty? Call Garden State Garage Floor Coating at (732) 477-3850 or click here for your free estimate.